Learn more on: What is ceramic • Vitreous China vs Fireclay • Rimless toilet technology • Certifications

60 YEARS OF ITALIAN HISTORY

July 12, 1955. SIMAS was born in Civita Castellana, which even at that time had a high capacity for manual production processes handed down from father to son. Today as yesterday, it is a company made up of people who are committed to developing concrete projects in which everyone works according to their skills. A stock company with 68 shareholders, 109 employees and 150,000 pieces produced annually. Strictly made in Italy, aimed at building, together, trends that are always up-to-date and contemporary and that last over time, the result of consolidated know-how and expertise handed down in the name of work ethic.

CRAFTSMANSHIP MEETS TECHNOLOGY

SIMAS prides itself in its dedication to “handcrafted” tradition and, at the same time, to continual evolution, based on two prerogatives: all strictly made in Italy and all strictly manufactured internally from casting and painting to the cooking tunnels and barcode system, with a path that goes from the internal logistics until the distribution. SIMAS, an emblem of Italian craftsmanship, continues to focus on the original principles: shared opinions, team work, loyal agents, prompt pre-sales and post-sales assistance.

WHAT IS CERAMIC?

Ceramic, from ancient Greek κέραμος, ‘kéramos’, that is ‘clay’, ‘pottery’, is an inorganic, non-metallic material, that may be folded in different shapes at its natural state and that becomes very steady after the firing phase. Ceramic is usually made of different materials: clays, feldspar, siliceous sands, iron oxides, alumina and quartz; when it is wet clay contains a large amount of water, a minimum of 25%, actually. When clay starts to dry, water evaporates from it and it is important to ensure this process is even, drying slowly, and naturally, as we do at SIMAS: after molding the sanitary ware dry in about 5 days, on a long and slow ‘travel’ on a 7 km chain passing all along the factory, exploiting the heat coming from the kiln. Complete drying does not take place until the piece is in the kiln; the last stage that happens during the firing process is vitrification. This is the hardening, tightening and finally the partial glassification of the clay. Vitrification results from fusions or melting of the various components of the clay.

VITREOUS CHINA VS FIRECLAY

In the field of ceramics sanitary ware, two different kind of materials are used: Vitreous China and Fine Fireclay. The production processes (molding, drying, enameling and firing) and the glaze are the same for both materials, the difference is in the characteristics of the ceramics: Vitreous China has a water absorption lower than 0,5% and a heavy pyroclastic shrinkage during the firing process that reaches 1250°C, 2282°F, whereas fireclay has an absorption lower than 9% and a lower pyroclastic shrinkage. These characteristics determine the use of one or another of the two materials (vitreous china for its lower water absorption is used for toilets and bidets and fireclay for objects of large dimensions).

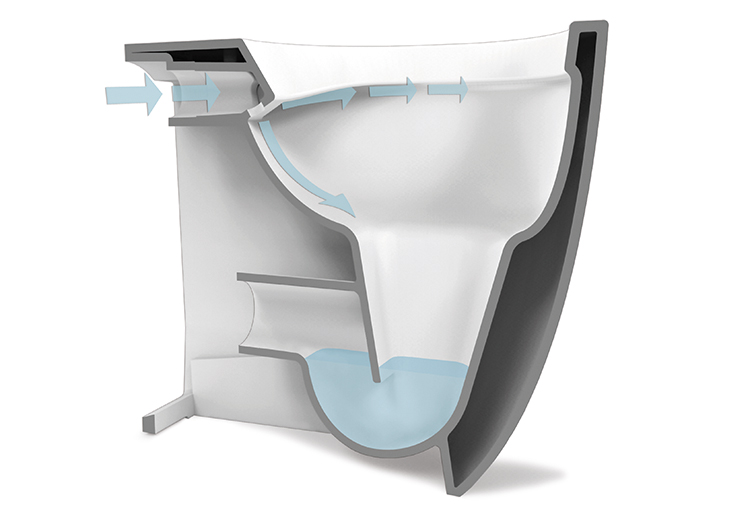

RIMLESS TOILET FLUSH TECHNOLOGY

Vignoni toilets are rimless, i.e. without the edge through which the water passes, an edge that represents approximately 20% of the inner basin of the toilet, and is usually difficult to clean. The new flushing system results in a much more linear design that is easier to clean. Flushing is more effective, with less splashing, for superior hygiene. And with a decidedly superior aesthetic effect.

CERTIFICATIONS

SIMAS is CERMET certified, with two important standards: UNI ISO 9001 – 2008 for process quality and UNI ISO 14001 – 2004 for correct environmental management. Regulations that stipulate the requirements for the creation of quality management systems and guarantee respect of the environment.

Toilets meet the WaterSense standards and are UPC certified, as are many of our sink models.